What Are Nano Liquid Screen Protector Machines?

Nano Liquid Screen Protector Machines are cutting-edge devices designed with the purpose of applying liquid screen protectors to electronic devices. Unlike traditional screen protectors that you have to stick onto your screens, these machines leverage advanced nano-coating technology. This technology forms a protective layer far thinner than regular protectors but offers superior durability and resistance.

These machines work by either spraying or applying a specialized liquid solution onto the screen surface. This solution chemically bonds with the display, ensuring a seamless and robust protection method. The process results in a finish that is not only ultra-smooth and scratch-resistant but also possesses water-repellent properties. Such sophisticated protection is ideal for professionals seeking high-quality screen defense or for anyone looking to extend the lifespan and preserve the pristine condition of their electronic screens.

Key Features to Consider in 2024 Models

Durability and Long-Lasting Protection

When selecting a nano liquid screen protector machine in 2024, durability should be one of the top priorities. It's essential to look for machines that offer robust protection against scratches and impact damage. Many of the modern models provide enhanced protection, ensuring a screen can remain unscathed for extended periods. The 2024 models are expected to meet advanced industry standards, which means they should provide a minimum of 2-3 years of effective screen safeguarding. This longevity is vital for users looking to maximize their investment in device protection.

Ease of Application Process

A seamless and straightforward application process is a critical feature for nano liquid screen protector machines in 2024. Machines with user-friendly operations are exceedingly valuable, particularly in commercial environments, as they reduce the training time required for operators. Look for features such as intuitive controls and clear instructions. These attributes help maximize application efficiency, which is crucial for businesses that need to process a high volume of devices quickly and effectively.

Compatibility with Multiple Device Types

Given the diverse range of electronic gadgets available today, compatibility with multiple device types is a significant feature to prioritize in 2024 models. It's essential to ensure that the machine can apply protectors to various devices, including smartphones, tablets, and even smartwatches. Furthermore, check if the model offers custom settings or interchangeable attachments that accommodate different screen sizes. This flexibility ensures that regardless of the device, you can provide reliable protection without the need for multiple machines.

Top Nano Liquid Screen Protector Machine of 2024

Professional-Grade Nano Coating Application

The latest nano liquid screen protector machines of 2024 are designed to deliver professional-grade application, ensuring that imperfections are minimized. When choosing these machines, it is crucial to look for models that feature high precision and even distribution capabilities for a flawless finish. These features allow businesses to offer superior screen protection, enhancing the durability and aesthetic of various devices.

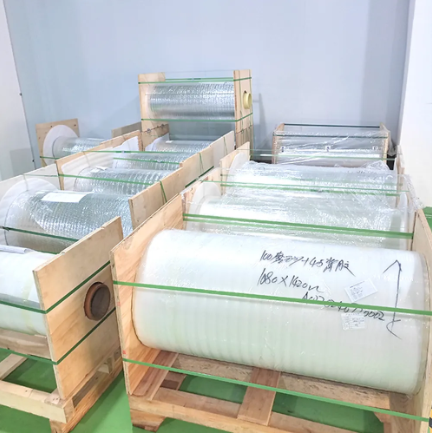

Included Accessories and Liquid Solutions

High-end nano coating machines often come with specialized accessories and liquid solutions, designed to enhance the application process. It's advisable to opt for machines that provide starter kits, containing all necessary items to initiate operations seamlessly. Typically, these kits include items such as bottles of coating liquid, cleaning sprays, and application wipes which are essential for achieving optimal results.

Ideal for High-Volume Commercial Use

For commercial settings, nano liquid screen protector machines need to support rapid and efficient handling of a large number of devices. Selecting models with robust builds and swift application times can drastically increase throughput, catering to high-volume needs. Such machines ensure that businesses can maintain peak performance and deliver quality results consistently, meeting the demands of commercial use effectively.

Benefits of Advanced Nano Coating Technology

Scratch Resistance and Enhanced Clarity

Nano coating technology offers superior scratch resistance while maintaining high screen visibility, revolutionizing screen protection. Studies indicate that these coatings significantly reduce visible scratches compared to traditional plastic protectors, providing a clearer and more durable surface. For example, nano coatings form a tighter bond with the glass surface of devices, enhancing resistance against everyday scratches. This ensures that the screen remains pristine, contributing to an optimal viewing experience.

Hydrophobic Properties for Daily Use

Hydrophobic properties in nano coatings improve user experiences by repelling water and oils, keeping screens cleaner longer. This feature is particularly beneficial for smartphones and tablets used in various environments. By repelling moisture and fingerprints, nano coatings minimize cleaning frequency, keeping screens pristine throughout the day. This is of great advantage to users who frequently handle their devices in damp or oily conditions, allowing screens to maintain their clarity and functionality over time.

How to Apply Nano Liquid Screen Protectors Properly

Step-by-Step Application Guide

Applying a nano liquid screen protector requires precision for the best results. First, clean the screen thoroughly using a microfiber cloth or an included cleaning solution to remove dust and fingerprints. Next, apply the nano liquid evenly across the screen. Ensure that you spread the liquid from edge to edge, maintaining a consistent layer. Let it dry for the recommended time, usually about 5-10 minutes. Remember to hold your device at a slight angle to avoid pooling of the liquid, which can lead to uneven protection. Proper preparation and technique are crucial to achieving a smooth, even finish and optimal screen protection.

Common Mistakes to Avoid

When applying nano liquid screen protectors, certain common mistakes can compromise the quality of protection. Failing to clean the screen thoroughly can trap debris under the coating, significantly affecting clarity and adhesion. Over-applying the liquid is another typical error, often leading to streaks and bubbles that mar the screen's surface. Furthermore, applying the liquid in a humid environment can extend drying times and introduce additional moisture, which may interfere with the bonding process. By understanding these pitfalls and approaching each step with care, one can greatly enhance the effectiveness of the screen protector, ensuring long-lasting protection.

FAQ

What is a Nano Liquid Screen Protector Machine?

A Nano Liquid Screen Protector Machine is a device designed to apply liquid screen protectors using advanced nano-coating technology, providing durable, scratch-resistant, and water-repellent protection for electronic screens.

How long does the protection last?

Most 2024 models offer protection for a minimum of 2-3 years, depending on usage and care.

Can these machines be used on all types of devices?

Yes, they generally offer compatibility with a variety of devices such as smartphones, tablets, and smartwatches, especially if equipped with custom settings or interchangeable attachments.

What are the main benefits of using nano coatings?

Nano coatings provide superior scratch resistance and hydrophobic properties, resulting in enhanced screen clarity and reduced cleaning frequency.

What should I consider when using these machines commercially?

Consider machines with robust builds and swift application processes to handle high volumes efficiently, maintaining quality and performance in commercial settings.

EN

EN

BG

BG

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS

BN

BN